Week 9: Mechanical Design

Assignment:

- Design a machine (mechanism+automation), including the end effector.

- Build the passive parts and operate it manually.

- Document the group project and your individual contribution.

This week goal is to fabricate a two axis machine in group and make it work manually.

We use the James Coleman and Nadya Peek project as a tutorial to construct our 2 axis drawing CNC, our goal is make it draw something.

Machines:

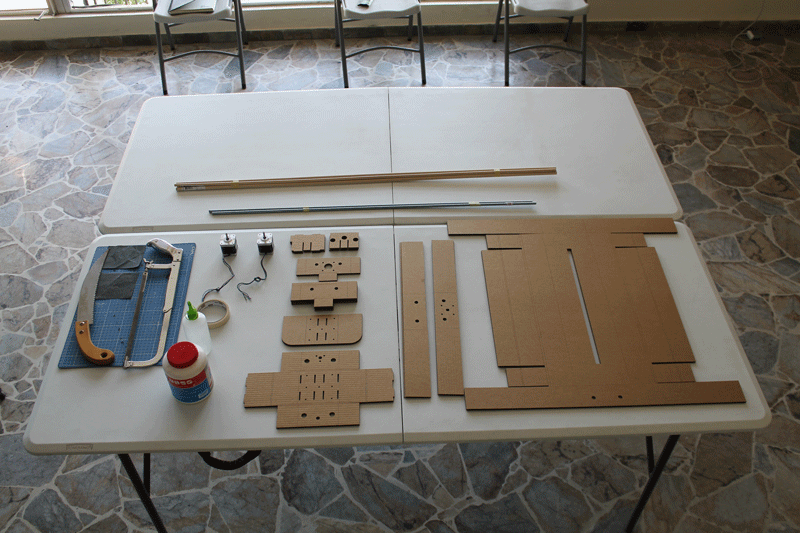

Materials:

- Cardboard sheets 30” x 40”

- Wooden round molding sticks 7/16” x 48”

- Threaded rod 3/8”

- Step motors Wantai 42BYGHM809

- Nuts and bolts

- Acrylic sheets 3mm

- Silicone liquid glue

- Adhesive velcro tape

GROUP PROJECT:

For this week we work in groups to design a machine and make it work. We decided to make a CNC drawing machine we called Maggy. The group web site is here.

INDIVIDUAL CONTRIBUTION:

My individual contribution for this assignment was cut in the laser all the cardboard pieces needed to assembly the boxes following step by step James and Nadya project.

I downloaded the original cutting files here and sent the file to cut to a Trotec Speedy 300 laser CO2, I used 3mm cardboard sheets.

Once all the pieces were cut, I separated them by type to be able to use them in order.

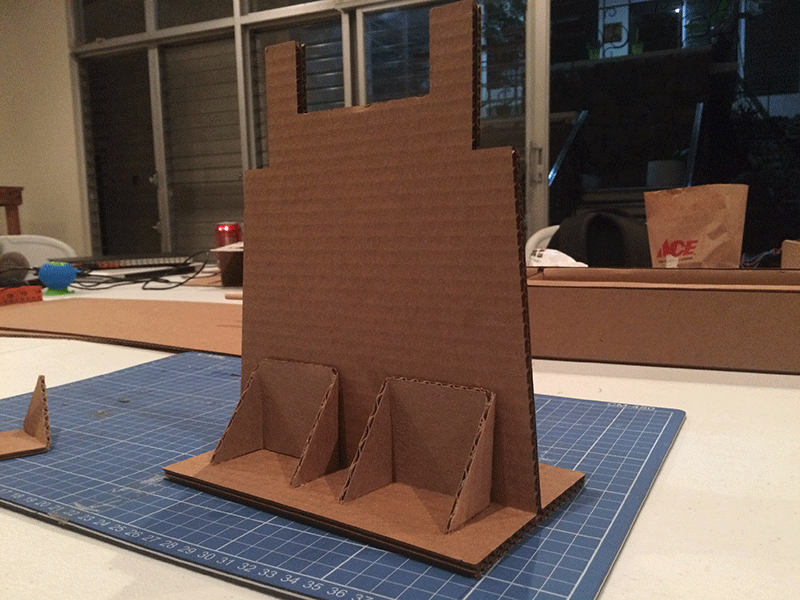

I also design a little triangle piece in order to fix a nut where the rod make its movements, otherwise, the cardboard was going to wear out with the movement.

To do that, we had to make a change in one of the inside pieces of the box which moves through the rod, because the space to fix the acrylic piece was too thin, so we made it wider.

My next contribution to the group was cut the stand that supports the assembled boxes. For this we need 4 identical pieces glued by pairs back to back.